Lithium Americas Expands Resource at Thacker Pass and Increases Phase 1 Capacity to Target 40,000 tpa Lithium Carbonate

VANCOUVER, British Columbia, Oct. 07, 2021 (GLOBE NEWSWIRE) -- Lithium Americas Corp. (TSX: LAC) (NYSE: LAC) ("Lithium Americas" or the "Company") is pleased to provide a project update for the Thacker Pass lithium project in Humboldt County, Nevada (“Thacker Pass” or the “Project”) including an increase in the Mineral Resource estimate to 13.7 million tonnes (“Mt”) of lithium carbonate equivalent (“LCE”) grading 2,231 parts per million lithium (“ppm Li”) of Measured and Indicated (“M&I”) and 4.4 Mt of LCE grading 2,112 ppm Li of Inferred Resources.

HIGHLIGHTS

- Expanded M&I Resource estimate to 13.7 Mt LCE at 2,231 ppm Li. The updated Mineral Resource estimate incorporates the Southwest Basin, change in cut-off grade and additional drilling since the 2018 M&I Resource of 6.0 Mt LCE at 2,917 ppm Li.

- Increased Phase 1 capacity of ongoing Feasibility Study to target 40,000 tpa lithium carbonate. Initial Phase 1 targeted capacity increased from 30,000-35,000 tpa to reflect the optimized mine plan and leaching efficiencies with the proposed 3,000 tpd sulfuric acid plant unchanged.

- Incorporating Phase 2 to target additional 40,000 tpa capacity. Feasibility Study is being designed to incorporate a potential Phase 2 expansion scenario to target total capacity of 80,000 tpa to meet potential partner and customer demand. The Company expects to provide an update on timing of the Feasibility Study by early 2022 to align with the strategic partnership process and ongoing engineering work.

- Permitting process on track with final decision expected in Q1 2022. All key State permits are expected to be released for public comment in Q4 2021. At the Federal level, a court hearing on the appeal of the Record of Decision is expected to take place in February 2022, with the ruling to follow shortly thereafter.

- Early-works construction expected to commence in H1 2022. Early-works includes roads, site preparation, water line and additional infrastructure to condense and de-risk the overall construction schedule.

- Discussions continue with potential strategic partners and customers. The Company has retained Greenhill & Co. to act as financial advisor for the Thacker Pass strategic partnership process.

- Developing integrated pilot plant to support increased scale. Working on an integrated pilot plant, expected to be operational in H1 2022, to support ongoing optimization work, confirm certain assumptions in the design and operational parameters and provide product samples for potential customers.

- Designed to minimize environmental footprint. Thacker Pass is being designed to incorporate carbon-free power as its primary energy source, state-of-the-art air emissions control technologies, a zero-water discharge process, water recycling technologies to reduce water consumption and adopt active reclamation to maintain low footprint. Environmental impact analysis is underway by Golder Associates to align with the proposed Feasibility Study design.

“As the US electric vehicle supply chain continues to grow, we remain committed to developing Thacker Pass with all of our stakeholders’ interests in mind,” said Jonathan Evans, President & CEO. “This includes ensuring we move the right project forward to align Thacker Pass with the growing needs of our potential customers and strategic partners.”

“The world needs more large-scale and environmentally responsible lithium projects to enable the clean energy transition,” added Mr. Evans. “With Thacker Pass moving closer towards construction, in Argentina our team remains focused on bringing the Caucharí-Olaroz lithium brine project online in the next twelve months as the largest new lithium carbonate operation in over 20 years.”

Updated Mineral Resource Estimate

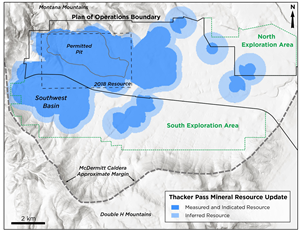

The Mineral Resource estimate has been updated from the 2018 model to include new drilling within the Plan of Operations and the South Exploration Area (Figure 1).

Figure 1: Thacker Pass Location and Mineral Resource Model Compared to the Boundary of 2018 Resource Model

https://www.globenewswire.com/NewsRoom/AttachmentNg/95a098ba-694c-4eea-aa52-2b6d15572cf3

Table 1 shows the changes compared to the April 5, 2018 Mineral Resource estimate.

Table 1: Updated Mineral Resource Estimate

| Category | Effective date of October 7, 2021 1,334 ppm Li cut-off grade | Effective date of April 5, 2018 2,000 ppm Li cut-off grade |

| Measured | 654.2 Mt 2,356 Average Li (ppm) 8.2 Mt LCE | 242.2 Mt 2,948 Average Li (ppm) 3.8 Mt LCE |

| Indicated | 499.4 Mt 2,067 Average Li (ppm) 5.5 Mt LCE | 143.1 Mt 2,864 Average Li (ppm) 2.2 Mt LCE |

| Total Measured and Indicated | 1,153.6 Mt 2,231 Average Li (ppm) 13.7 Mt LCE | 385.3 Mt 2,917 Average Li (ppm) 6.0 Mt LCE |

| Inferred | 391.6 Mt 2,112 Average Li (ppm) 4.4 Mt LCE | 147.4 Mt 2,932 Average Li (ppm) 2.3 Mt LCE |

NOTES for the October 7, 2021 Resource:

| ||

The bulk of the increase in the Mineral Resource tonnage is primarily due to (1) change in cut-off grade to maximize and optimize the available lithium for processing, a decision driven by market demands and supported by changes made to the process flowsheet, as well as to comply with updated Canadian Institute of Mining and Metallurgy (“CIM”) (2019) best practice guidelines to use a break-even cut-off grade and show mineability with economic pit optimization evaluation; (2) an increase in the number of drill holes from 276 to 366; and (3) a larger area covered by the new drill holes.

To illustrate sensitivity to cut-off grade, using the same cut-off of 2,000 ppm Li as the April 5, 2018 Mineral Resource estimate, the comparative Measured and Indicated estimate is 9.0 Mt LCE (average 2,749 ppm Li) with Inferred at 2.6 Mt LCE (average 2,703 ppm Li).

Lithium Americas affirms that the updated Mineral Resource estimate does not constitute a material change and does not affect the integrity of the Resources and Reserves used in the preliminary feasibility study for Thacker Pass, “Technical Report on the Pre-Feasibility Study for the Thacker Pass Project, Humboldt County, Nevada, USA dated effective date August 1, 2018 (the “PFS”).

Partnership Process and Feasibility Study

Partnership Process

The Company expects to provide an update on timing of the Feasibility Study by early 2022, to align with the strategic partnership process and ongoing engineering work.

Lithium Americas has retained Greenhill & Co. to act as financial advisor for the Thacker Pass strategic partnership process.

Feasibility Study for Phases 1 and 2

Lithium Americas continues to advance the ongoing Feasibility Study targeting an increased initial production capacity to 40,000 tonnes per annum (“tpa”) of lithium carbonate (“Phase 1”) from 30,000-35,000 tpa, previously. The increased target capacity reflects optimizations to the mine plan and leaching efficiencies, maintaining the same proposed 3,000 tonnes per day (“tpd”) sulfuric acid plant and water usage. The Company is continuing to optimize engineering to complete the capital cost estimate and incorporate the impact of inflationary pressure, permit requirements and an increase in processing equipment.

In addition, the Company plans to include an expansion scenario to target total capacity of 80,000 tpa of lithium carbonate. The addition of a 40,000 tpa expansion (“Phase 2”), is designed to demonstrate Thacker Pass’ ability to scale production and align with potential customers’ and partners’ longer-term demands. The Phase 2 expansion scenario would entail additional time required to amend and meet permitting requirements beyond Phase 1.

To meet potential customer and partner needs, the Company continues to also advance engineering to consider an option for a 20,000 tpa lithium hydroxide chemical conversion plant.

Process Engineering and Design

Mine Plan and Processing Optimization

Over the past year, Lithium Americas has grown the engineering and technical team and continues to further optimize the mine plan and process. Optimization work is focused on maximizing lithium carbonate production in Phase 1 without increasing the size of the proposed 3,000 tpd sulfuric acid plant or water usage. Improvements include a mine plan focused on the illite clay and processing technologies to increase yield. When compared to smectite clay, illite clay displays higher leaching efficiencies and generally has higher lithium concentrations, as well as contains fewer impurities such as magnesium and calcium. Process changes completed include ore beneficiation, magnesium sulfate crystallization and improvements to the lithium carbonate circuit.

The Company is targeting total Phase 2 production capacity of 80,000 tpa within the same mining footprint as the permitted pit boundary. The team is advancing the mine engineering and combining the Phase 1 optimization and process improvements to achieve this increased production level.

Lithium Technical Development Center Collaboration with UNR

Working in collaboration with University of Nevada, Reno (“UNR”), the existing process testing facility will be relocated to a new facility in Reno and expanded to run the full Thacker Pass flowsheet to produce lithium carbonate samples. This Lithium Technical Development Center will also perform tests on other lithium deposits such as spodumene and brine. The integrated pilot plant is expected to be in operation in the first half of 2022 to support ongoing optimization work, confirm certain assumptions in the design and operational parameters and provide product samples for potential customers.

Regulatory and Permitting

Federal Permits

The Record of Decision (“ROD”) was received in January 2021 from the Bureau of Land Management (“BLM”). In February 2021, claims were filed against the BLM to appeal the issuance of the ROD. Injunction requests over the Company’s plan to begin pre-construction work were denied in Q3 2021. A court hearing on the appeal is expected to take place in February 2022, with the ruling to follow shortly thereafter.

State Permits

Three key state-level permits are expected to be published in draft form by the Nevada Department of Environmental Protection (“NDEP”) for public comment in Q4 2021: (1) Water Pollution Control Permit, (2) Mine Reclamation Permit and (3) Class II Air Permit. The Company expects to have final versions of these permits in December 2021.

The Company expects that early-works on the water line could begin as early as February 2022, once permits are received. Other early-works are expected to begin in H1 2022, including roads, site preparation and additional infrastructure, to condense and de-risk overall construction schedule.

Water Rights

A decision on the Company’s water rights transfer application by the state engineer to transfer the Company’s existing water rights, which is expected to provide sufficient water for all of Phase 1, is anticipated by Q1 2022.

Environmental and Social Responsibility

Fort McDermitt Paiute and Shoshone Tribe Benefits Agreement

The Company has presented a benefits agreement to the Fort McDermitt Paiute and Shoshone Tribe. Respecting the rights, culture, aspirations and interests of the local communities directly affected by the development and operation of Thacker Pass and working collaboratively towards mutually beneficial relationships remains a key priority for the Company.

Community Engagement

Through engagement with the community, the Company continues to enthusiastically participate in the Negotiating Work Group (‘Work Group”) along with selected members of the Thacker Pass Concerned Citizens Group (“TPCCG”). The purpose of the Work Group is to develop agreements supported by scientific data and community buy-in to guide the construction and operations of Thacker Pass. The Work Group focuses its discussions on identifying solutions that protect the safety and well-being of community members. The Work Group continues to meet every two weeks, and the Company is committed to quickly resolving community issues and building healthy relations for years to come.

Carbon Footprint and Water Impact Analysis

The Company has engaged Golder Associates to determine the estimated operational carbon footprint and water impact of the operations of both Thacker Pass and Caucharí-Olaroz. Thacker Pass is designed to minimize environmental impact by approximately 45 MW of carbon-free power from the 3,000 tpd sulfuric acid plant as a primary power source, designing the project to avoid sensitive habitat, minimizing water consumption and air emissions through state-of-the-art technologies, as well as maximizing production levels within the same footprint as previously considered.

Socioeconomic and Environmental Study with UNR

Lithium Americas has a long-standing relationship with UNR, originally partnering with UNR’s Department of Agriculture, Veterinary and Rangeland Sciences to establish the Great Basin Sagebrush Restoration Fund in 2017. The Company has recently formalized a relationship with the Department of Mining and Metallurgical Engineering at UNR’s Mackay School of Earth Sciences and Engineering to assess the socioeconomic and environmental footprint for Thacker Pass. Professor Ehsan Bahidi, Ph.D. will run the two-year program, which will include development of a life cycle inventory database, quantifying the environmental performance of lithium production from claystone ore and analysis of socioeconomic impacts from activity at Thacker Pass with other lithium production facilities around the world.

Mineral Resource Estimate Methodology

A block model was created by mining contractor Sawtooth Mining, LLC, a subsidiary of NACCO Industries, Inc. (NYSE: NC), and part of the NACCO Natural Resources family, using Maptek’s Vulcan 3D subsurface geologic modeling software. A regular block model with a block size of 25 m by 25 m by 1 m was generated. A Vulcan ISIS database was designed and populated with native geologic data from Excel datasheets containing borehole assays, collars, lithological and survey data which were exported from the Company’s Hexagon Mining Drillhole Manager (Torque) database. A composited database was then created from this native ISIS database. A compositing run length of 1 m was chosen based upon mining assumptions of potential waste removal. This composited database used existing geocodes from the Torque database to isolate the compositing of grades to each correlated geologic lithology. Lithium grades were interpolated for clay/ash lithologies in the block model through ordinary kriging modeling method from a 1 m composited quality database.

Fault traces were connected to generate seven faulted block zones. These faulted block zones were used to limit the lithium grade estimation to the blocks and drill holes existing within each representative faulted block zone. Lithium grades have been estimated throughout the block model using the composited assay database with the declustered weights through ordinary kriging (OK) modeling method. Only clay/ash ore material was estimated for lithium grade and each domain was estimated independently.

In accordance with CIM Definition Standards along with Mineral Resource and Mineral Reserve Estimation Best Practice Guidelines (2019) a resource economical pit shell has been derived from performing a pit optimization calculation using Vulcan Software. The pit optimization utilized the appropriate cost inputs and the lithium cut-off grade of 1,334 ppm to determine the economic resource pit shell for the final resource estimation from the block model.

Quality Assurance and Quality Control

The data collection and analysis procedures employed to develop the information presented in this news release use industry-standard quality techniques and procedures.

Sampling procedure and assaying methods were as follows:

- Drilled core was brought from the field to the Company’s core shed located in Orovada, Nevada. The boxes of core were logged, photographed, cut and sampled by Company employees and consultants. The geologist determined the length of the assay samples by lithology and averaged 1.60 m. The core was cut in half with diamond blade saws, using fresh water and half bagged for sampling. For duplicate samples, one half of the core is cut in half again and the two halves are bagged and sampled separately to test sampling and assay precision. Each sample was assigned a unique identification number to ensure security and anonymity. Randomly inserted in the sample stream were QA/QC samples, which represent 10.1% of the total assays. The QA/QC samples include blanks to test for contamination, high and low-grade lithium standards to test for accuracy and duplicates to test for precision.

- Drilled core samples were collected from the core shed by ALS Ltd. (“ALS”), an independent analytical testing services provider, and transported to their lab in Reno, Nevada. At ALS, the samples were dried at a maximum temperature of 60 degrees Celsius and the entire sample was then crushed with a jaw crusher to 90% passing a ten-mesh screen. Nominal 250 gram splits were taken for each sample using a rifle splitter. This split is pulverized using a ring mill to 90% passing a 150-mesh screen.

- ALS’ analysis included four-acid digestion and inductively coupled atomic emission plasma spectroscopy to ensure that elevated metal concentrations were not present, which would interfere with inductively coupled plasma mass spectroscopy analyses.

QA/QC protocols included:

- High, low and blank standards were inserted in random sampling intervals. These samples were also assigned a blinded sample identification number.

- Duplicate samples were taken approximately every 30.48 meters. Each was assigned a blinded identification number.

QA/QC statistical evaluations and results:

- 2017-2018 LNC Drilling

- Eight low grade samples out of 139 assays fell outside the certified two standard deviation. All eight were within 70 ppm of falling within the two standard deviation criteria. Seven high-grade samples out of 140 assays fell outside the certified two standard deviation. All were biased low by as much as 135 ppm.

- All blank standards reported less than 100 ppm Lithium.

- All assay standards showed minimal bias drift with time.

- 365 duplicate ¼ core samples, 730 assays, returned a R2 correlation value of 0.9901.

- One sample pair was withdrawn.

- 2010-2011 WLC Drilling

- Twelve low grade samples out of 305 assays fell outside the certified two standard deviation. Eight were within 90 ppm of falling within the two standard deviation criteria, three samples were withdrawn as likely HG mis-sampling and one withdrawn as a bad assay. Fifteen high-grade samples out of 303 assays fell outside the certified two standard deviation. Four samples are withdrawn as likely LG mis-sampling and the remaining within 170 ppm of falling within the two standard deviation criteria.

- Seventeen blank standards out of 308 samples exceeded the 100 ppm Lithium threshold. The max exceedance was by 156 ppm.

- All assay standards showed minimal bias drift with time.

- 247 duplicate ¼ core samples, 494 assays, returned a R2 correlation value of 0.9732.

National Instrument 43-101 Disclosure

The scientific and technical information disclosed in this news release relating to the Resource Estimate has been prepared and approved by Randal Burns, B.Sc., SME, VP Exploration at Lithium Nevada Corp., a wholly owned subsidiary of Lithium Americas, a “Qualified Person" as defined by National Instrument 43-101 ("NI 43-101").

Mr. Burns has verified the data disclosed in this news release and no limitations were imposed on the verification process. In the course of data verification, and for purposes of QA/QC, Mr. Burns, among other things, reviewed or developed the following types of information for the deposit:

- Geologic maps and cross sections

- Block model methods, parameters, tabulations, and model results

- Estimated mining and process costs

- Resource determination procedures and results to assure reasonable expectation of economic extraction

- Sampling procedure and assaying methods

- QA/QC protocols and results, including:

- Analysis of inserted standards

- Analysis of inserted blanks

- Confirmation of assays from a check lab

- Reverse Circulation versus Diamond Drilling

- ¼ core sampling and assay versus ½ core sampling and assay

- Spot checks of the data base against original certificates of assay

- Statistical evaluations and studies

- Checked reliability of historic information and established protocol for acceptance or rejection of legacy data

Unless otherwise indicated, Lithium Americas has prepared the technical information in this news release (“Technical Information”) based on information contained in the technical reports, news releases and MD&A’s (collectively the “Disclosure Documents”) available under the company’s SEDAR profile at www.sedar.com. The Disclosure Documents are each intended to be read as a whole, and sections should not be read or relied upon out of context. The Technical Information is subject to the assumptions and qualifications contained in the Disclosure Documents. Readers are advised that Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The Company does not view the change in Mineral Resources as material until the Mineral Resources are included in an updated mine plan. Lithium Americas affirms that the updated Mineral Resource estimate does not constitute a material change and does not affect the integrity of the Resources and Reserves used in the PFS.

The Technical Information in this news release has been reviewed and approved by Rene LeBlanc, PhD, SME, Chief Technical Officer of Lithium Americas, a Qualified Person as defined by NI 43-101.

Other than as described in the Company's Disclosure Documents, there are no known legal, political, environmental or other risks that could materially affect the potential development of the Mineral Resources at this point of time.

About Lithium Americas

Lithium Americas is a development-stage company with projects in Jujuy, Argentina and Humboldt County, Nevada, United States. The Company trades on both the Toronto Stock Exchange and on the New York Stock Exchange, under the ticker symbol “LAC”.

For further information contact:

Investor Relations

Telephone: 778-656-5820

Email: ir@lithiumamericas.com

Website: www.lithiumamericas.com

Forward-Looking Statements

This news release contains “forward-looking information” and “forward-looking statements” (which we refer to collectively as forward-looking information) under the provisions of applicable securities legislation. All statements, other than statements of historical fact, are forward-looking information. Forward-looking statements in this news release are made as of the date of this news release. Examples of forward-looking statements herein include, among other things, statements related to: the estimated amount and grade of Mineral Resources for the Thacker Pass project (the “Project”); timing, results and completion of a feasibility study and to make a construction decision for the Project, including an expected increase to total production capacity; estimates of future production, including ore processed and metal recovered; results of the engineering optimization and design work underway to advance the feasibility study; expected outcomes and timings of permit applications, environmental studies and surveys, and other environmental matters; the Company receiving and maintaining permits as anticipated; expected timing and outcome of litigation concerning the Project; timing and extent of early-works construction for the Project; the potential for Project partnership and financing scenarios, including potential government loan applications; expected timing and start-up of an integrated pilot plant; that the Project design, technologies utilized and environmental impacts will be as anticipated; the support of local communities and tribes for the Project; market demand for the Company’s products and future product offerings to satisfy such demand; commencement of production at the Caucharí-Olaroz project, which is held and operated through an entity in Argentina under a co-ownership arrangement with third parties; and successful operation of the Caucharí-Olaroz project under the co-ownership structure.

Forward-looking information is based upon a number of risks, factors and assumptions that, if untrue, could cause the actual results, performance or achievements of the Company to be materially different from future results, performance or achievements expressed or implied by such information. Such information reflects the Company’s current views with respect to future events and is necessarily based upon a number of assumptions that, while considered reasonable by the Company today, are inherently subject to significant uncertainties and contingencies. These risks, factors and assumptions include, among others: consistencies of mineralization and ore grades; mine plan design and costing, including processing and mining costs; the rate of recovery of lithium from the ore as a result of leach extraction and processing methods, and changes to such recovery rate when scaled; changes to project parameters as plans continue to be refined; current technological trends; impacts of inflation and additional process equipment on cost estimation and Project CAPEX; changes to the Company’s current and future business plans and the strategic alternatives available to the Company; the ability of the Company to fund, advance and develop its projects; completion of optimization work and a feasibility study for the Project that is economic; receipt and maintenance of permits and other regulatory approvals on terms acceptable to the Company; successful outcome of litigation involving the Project; personnel, machinery and equipment being secured within estimated timelines and at estimated prices; risks related to Project infrastructure; demand, supply and pricing for lithium; currency exchange rates; stock market conditions generally; a cordial business relationship among the Company and its partners; positive outcomes from consultations with local communities and tribes; and the impact of taxation laws and general economic and political conditions in the U.S. and other jurisdictions where the Company conducts business.

Additional risks, assumptions and other factors upon which forward-looking information is based, as it pertains to the Company and its properties, are set out in the Company’s management discussion and analysis and most recent annual information form, copies of which are available on SEDAR at www.sedar.com.

All estimates of Mineral Resources included in this news release have been prepared in accordance with NI 43-101 and the CIM Definition Standards on Mineral Resources, which differ in certain material respects from the mineral property disclosure requirements of the U.S. Securities and Exchange Commission applicable to domestic United States reporting companies that became effective on February 25, 2019. Accordingly, the estimates reported by the Company may not be comparable with information reported by U.S. domestic reporting companies.

Although the Company has attempted to identify important risks and assumptions, given the inherent uncertainties in such forward-looking information, there may be other factors that cause results to differ materially. Forward-looking information is made as of the date hereof and the Company does not intend, and expressly disclaims any obligation to update or revise the forward-looking information contained in this news release, except as required by applicable law. Accordingly, readers are cautioned not to place undue reliance on forward-looking information.

APPENDIX – MINERAL RESOURCE ESTIMATE AND DRILLING

Table 2: Mineral Resource Estimate as of October 7, 2021

| Category | Tonnage (000’s t) | Average Lithium (ppm) | LCE Quantity (000’s t) |

| Measured | 654,192 | 2,356 | 8,204 |

| Indicated | 499,436 | 2,067 | 5,495 |

| Total Measured and Indicated | 1,153,628 | 2,231 | 13,699 |

| Inferred | 391,577 | 2,112 | 4,401 |

Notes:

| |||

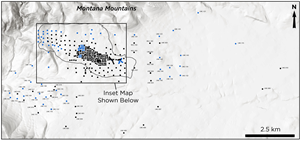

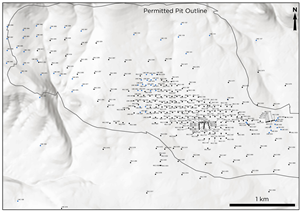

Figure 2a – Drill Hole Location Map

https://www.globenewswire.com/NewsRoom/AttachmentNg/35bf5830-814c-4c02-a49f-8c88e3f515f3

Figure 2b – Drill Hole Location Map

https://www.globenewswire.com/NewsRoom/AttachmentNg/b5504cc1-6fce-42c5-9514-c6e902c0e5d2

Table 3 – All Thacker Pass Drilling Used in Mineral Resource Estimate with an Effective Date of October 7, 2021

| Hole | Total Depth (m) | Overburden (m) | Length (m) >1,334 ppm Li | Average Li (ppm) | Maximum Li (ppm) | Easting | Northing |

| LNC-001 | 186.5 | 13.3 | 75.3 | 3,028 | 6,100 | 410,649 | 4,616,569 |

| LNC-002 | 61.0 | 0.0 | 61.0 | 178 | 273 | 410,602 | 4,616,216 |

| LNC-003 | 97.4 | 33.6 | 0.3 | 2,480 | 2,480 | 410,644 | 4,615,963 |

| LNC-004 | 46.4 | 15.8 | 1.6 | 1,450 | 1,450 | 410,610 | 4,615,822 |

| LNC-005 | 61.0 | 0.0 | 61.0 | 178 | 990 | 410,238 | 4,615,484 |

| LNC-006 | 61.0 | 0.0 | 61.0 | 153 | 379 | 412,393 | 4,615,216 |

| LNC-007 | 83.1 | 0.0 | 83.1 | 118 | 411 | 413,679 | 4,616,174 |

| LNC-008 | 76.2 | 46.0 | 0.5 | 1,470 | 1,470 | 413,131 | 4,615,502 |

| LNC-009 | 231.7 | 96.2 | 52.8 | 2,302 | 4,050 | 417,579 | 4,616,784 |

| LNC-010 | 212.5 | 149.4 | 23.0 | 1,898 | 2,550 | 418,256 | 4,617,540 |

| LNC-011 | 71.8 | 6.1 | 34.1 | 2,392 | 3,950 | 409,813 | 4,616,848 |

| LNC-012 | 54.1 | 0.0 | 54.1 | 94 | 690 | 409,213 | 4,616,006 |

| LNC-013 | 121.9 | 35.7 | 43.2 | 2,522 | 6,170 | 408,685 | 4,616,478 |

| LNC-014 | 76.3 | 62.3 | 0.8 | 1,340 | 1,340 | 409,098 | 4,616,247 |

| LNC-015 | 122.4 | 3.2 | 66.2 | 2,852 | 6,340 | 409,693 | 4,616,623 |

| LNC-016 | 95.3 | 13.0 | 52.1 | 2,697 | 5,350 | 408,450 | 4,616,716 |

| LNC-017 | 45.8 | 4.5 | 18.3 | 2,695 | 5,800 | 409,021 | 4,616,800 |

| LNC-018 | 122.7 | 3.6 | 62.4 | 2,723 | 5,820 | 409,854 | 4,616,969 |

| LNC-019 | 83.1 | 3.1 | 64.2 | 3,387 | 6,420 | 409,924 | 4,618,708 |

| LNC-020 | 78.5 | 10.5 | 51.2 | 3,549 | 6,920 | 409,746 | 4,618,748 |

| LNC-021 | 80.1 | 6.0 | 64.1 | 3,680 | 7,660 | 409,600 | 4,618,773 |

| LNC-022 | 46.5 | 37.6 | 1.6 | 1,790 | 1,790 | 413,414 | 4,618,162 |

| LNC-023 | 46.6 | 22.3 | 5.6 | 1,970 | 2,750 | 413,427 | 4,617,142 |

| LNC-024 | 54.9 | 15.1 | 21.4 | 2,788 | 4,980 | 413,414 | 4,617,422 |

| LNC-025 | 77.0 | 34.5 | 1.9 | 1,350 | 1,350 | 413,770 | 4,618,532 |

| LNC-026 | 95.1 | 20.6 | 64.4 | 3,173 | 5,550 | 409,915 | 4,618,894 |

| LNC-027 | 106.7 | 6.3 | 71.0 | 3,299 | 5,870 | 410,106 | 4,618,841 |

| LNC-028 | 89.2 | 0.0 | 71.7 | 3,302 | 7,230 | 409,748 | 4,618,887 |

| LNC-029 | 107.5 | 13.8 | 65.9 | 3,297 | 5,480 | 410,274 | 4,618,851 |

| LNC-030 | 76.2 | 8.4 | 59.5 | 3,207 | 6,880 | 410,639 | 4,618,095 |

| LNC-031 | 90.7 | 11.1 | 68.2 | 3,413 | 7,540 | 410,940 | 4,618,181 |

| LNC-032 | 80.0 | 11.1 | 61.6 | 3,523 | 7,210 | 410,950 | 4,618,112 |

| LNC-033 | 89.2 | 9.3 | 68.5 | 3,416 | 7,620 | 410,937 | 4,618,057 |

| LNC-034 | 61.8 | 4.4 | 49.5 | 3,913 | 8,040 | 410,942 | 4,617,995 |

| LNC-035 | 40.5 | 2.5 | 32.5 | 3,989 | 7,720 | 410,880 | 4,617,999 |

| LNC-036 | 92.3 | 3.8 | 79.5 | 3,204 | 7,440 | 410,883 | 4,618,052 |

| LNC-037 | 92.2 | 15.7 | 63.3 | 3,270 | 6,990 | 410,884 | 4,618,111 |

| LNC-038 | 95.3 | 13.8 | 68.7 | 3,284 | 6,940 | 410,877 | 4,618,181 |

| LNC-039 | 89.2 | 10.9 | 71.5 | 3,255 | 7,500 | 410,815 | 4,618,180 |

| LNC-040 | 87.7 | 12.4 | 69.9 | 3,594 | 7,950 | 410,744 | 4,618,183 |

| LNC-041 | 45.7 | 2.5 | 36.3 | 3,729 | 7,040 | 410,697 | 4,618,048 |

| LNC-042 | 95.3 | 15.3 | 73.2 | 3,357 | 6,990 | 410,707 | 4,618,120 |

| LNC-043 | 91.0 | 16.3 | 69.8 | 3,289 | 7,180 | 410,947 | 4,618,238 |

| LNC-044 | 89.3 | 11.5 | 68.8 | 3,593 | 6,960 | 410,881 | 4,618,239 |

| LNC-045 | 84.6 | 16.0 | 63.0 | 3,519 | 6,910 | 410,810 | 4,618,247 |

| LNC-046 | 66.5 | 17.4 | 46.3 | 3,394 | 7,320 | 410,744 | 4,618,246 |

| LNC-047 | 88.7 | 14.5 | 62.9 | 3,567 | 7,390 | 410,699 | 4,618,242 |

| LNC-048 | 92.3 | 16.7 | 63.5 | 3,488 | 6,900 | 410,694 | 4,618,187 |

| LNC-057 | 92.3 | 14.2 | 72.2 | 3,329 | 7,370 | 410,836 | 4,618,363 |

| LNC-058 | 95.1 | 16.0 | 66.5 | 3,207 | 7,950 | 410,829 | 4,618,118 |

| LNC-059 | 113.7 | 6.1 | 77.3 | 3,173 | 6,170 | 410,908 | 4,618,483 |

| LNC-060 | 95.3 | 0.0 | 73.6 | 3,134 | 6,620 | 410,829 | 4,618,058 |

| LNC-061 | 112.1 | 9.9 | 69.5 | 3,093 | 5,670 | 410,844 | 4,618,485 |

| LNC-062 | 97.0 | 14.9 | 75.6 | 3,146 | 6,700 | 410,767 | 4,618,116 |

| LNC-063 | 90.8 | 22.2 | 65.8 | 3,314 | 6,450 | 410,852 | 4,618,420 |

| LNC-064 | 54.2 | 0.0 | 47.2 | 3,298 | 6,760 | 410,768 | 4,618,054 |

| LNC-065 | 96.9 | 23.4 | 64.7 | 3,410 | 6,460 | 410,784 | 4,618,424 |

| LNC-066 | 87.7 | 13.1 | 65.5 | 3,605 | 6,640 | 410,949 | 4,618,301 |

| LNC-067 | 58.8 | 11.8 | 35.2 | 3,718 | 6,770 | 409,785 | 4,618,511 |

| LNC-068 | 92.3 | 13.3 | 70.2 | 3,397 | 6,740 | 410,889 | 4,618,298 |

| LNC-069 | 54.2 | 11.8 | 30.0 | 4,123 | 8,440 | 409,857 | 4,618,486 |

| LNC-070 | 84.7 | 14.6 | 62.4 | 3,373 | 7,160 | 410,894 | 4,618,363 |

| LNC-071 | 101.4 | 16.2 | 68.1 | 3,610 | 7,530 | 410,947 | 4,618,364 |

| LNC-072 | 101.4 | 21.0 | 56.5 | 3,326 | 7,920 | 410,951 | 4,618,424 |

| LNC-073 | 77.1 | 10.2 | 40.4 | 3,633 | 7,770 | 409,638 | 4,618,498 |

| LNC-074 | 90.8 | 21.4 | 54.1 | 3,525 | 6,840 | 410,896 | 4,618,423 |

| LNC-075 | 69.4 | 8.8 | 45.6 | 3,922 | 7,690 | 409,996 | 4,618,446 |

| LNC-076 | 98.3 | 14.7 | 68.5 | 3,461 | 8,100 | 410,799 | 4,618,373 |

| LNC-077 | 75.5 | 11.6 | 52.5 | 3,728 | 7,220 | 410,107 | 4,618,367 |

| LNC-078 | 88.0 | 13.4 | 66.1 | 3,467 | 6,770 | 410,787 | 4,618,304 |

| LNC-079 | 63.6 | 4.0 | 43.1 | 4,228 | 6,970 | 409,991 | 4,618,300 |

| LNC-080 | 94.4 | 20.0 | 65.3 | 3,604 | 7,130 | 410,746 | 4,618,366 |

| LNC-081 | 98.7 | 0.0 | 98.7 | 30 | 60 | 409,623 | 4,618,239 |

| LNC-082 | 90.7 | 16.0 | 68.4 | 3,494 | 7,430 | 410,745 | 4,618,305 |

| LNC-083 | 37.7 | 0.0 | 20.9 | 3,768 | 5,180 | 411,131 | 4,617,984 |

| LNC-084 | 67.8 | 6.8 | 45.8 | 3,687 | 7,540 | 411,769 | 4,618,190 |

| LNC-085 | 113.6 | 4.7 | 80.4 | 3,069 | 6,220 | 410,964 | 4,618,484 |

| LNC-087 | 113.5 | 21.8 | 67.2 | 3,043 | 5,640 | 410,104 | 4,618,990 |

| LNC-088 | 108.9 | 8.1 | 66.3 | 2,888 | 5,560 | 409,916 | 4,619,034 |

| LNC-089 | 99.1 | 32.6 | 64.0 | 2,970 | 5,450 | 409,753 | 4,619,030 |

| LNC-090 | 75.9 | 14.5 | 54.1 | 3,043 | 4,880 | 409,593 | 4,619,055 |

| LNC-091 | 85.7 | 16.3 | 57.9 | 3,402 | 6,990 | 409,595 | 4,618,935 |

| LNC-092 | 152.1 | 8.4 | 25.7 | 4,391 | 7,140 | 409,600 | 4,618,657 |

| LNC-093 | 106.0 | 0.0 | 24.9 | 4,833 | 7,550 | 409,440 | 4,618,920 |

| LNC-094 | 85.8 | 0.0 | 60.4 | 3,520 | 6,380 | 409,442 | 4,619,010 |

| LNC-095 | 79.0 | 0.0 | 79.0 | 58 | 93 | 409,366 | 4,618,811 |

| LNC-096 | 73.3 | 2.4 | 23.3 | 4,725 | 6,670 | 409,255 | 4,618,779 |

| LNC-097 | 111.4 | 0.0 | 16.6 | 4,457 | 6,100 | 409,254 | 4,618,913 |

| LNC-098 | 125.0 | 0.0 | 37.6 | 3,572 | 6,130 | 409,258 | 4,619,051 |

| LNC-099 | 64.6 | 9.4 | 50.5 | 3,574 | 7,870 | 409,246 | 4,618,634 |

| LNC-100 | 43.9 | 3.7 | 13.4 | 3,189 | 6,250 | 409,410 | 4,618,524 |

| LNC-101 | 61.0 | 0.0 | 41.3 | 4,028 | 6,400 | 409,438 | 4,618,618 |

| LNC-102 | 47.2 | 2.3 | 10.6 | 5,664 | 7,110 | 409,447 | 4,618,763 |

| LNC-103 | 182.9 | 1.2 | 181.7 | 27 | 84 | 409,621 | 4,618,238 |

| LNC-104 | 152.6 | 4.4 | 66.7 | 2,777 | 5,870 | 409,621 | 4,617,689 |

| LNC-105 | 81.9 | 16.5 | 20.9 | 2,276 | 4,130 | 408,951 | 4,617,146 |

| LNC-106 | 87.8 | 0.0 | 22.9 | 2,955 | 4,940 | 409,354 | 4,617,059 |

| LNC-107 | 56.0 | 1.8 | 23.1 | 2,347 | 4,440 | 409,273 | 4,616,710 |

| LNC-108 | 20.9 | 0.0 | 20.9 | 200 | 1,070 | 408,652 | 4,616,906 |

| LNC-109 | 152.9 | 12.5 | 63.1 | 2,555 | 5,050 | 408,684 | 4,616,627 |

| LNC-110 | 36.5 | 2.7 | 33.7 | 397 | 1,070 | 409,702 | 4,616,127 |

| LNC-111 | 167.6 | 84.2 | 21.1 | 2,059 | 3,080 | 409,215 | 4,616,000 |

| LNC-112 | 89.6 | 3.3 | 3.3 | 1,487 | 1,540 | 409,404 | 4,616,312 |

| LNC-113 | 128.9 | 39.4 | 60.6 | 2,554 | 5,360 | 408,438 | 4,616,537 |

| LNC-114 | 178.5 | 114.9 | 27.0 | 2,390 | 3,490 | 409,700 | 4,616,131 |

| LNC-115 | 167.1 | 132.4 | 7.6 | 1,658 | 1,900 | 416,598 | 4,618,476 |

| LNC-116 | 158.5 | 0.0 | 21.5 | 2,909 | 5,290 | 409,012 | 4,617,749 |

| LNC-117 | 117.9 | 0.0 | 66.4 | 2,816 | 6,170 | 409,512 | 4,616,583 |

| LNC-118 | 155.5 | 8.3 | 79.1 | 2,847 | 5,630 | 409,898 | 4,616,825 |

| LNC-119 | 116.3 | 0.0 | 116.3 | 35 | 133 | 408,386 | 4,617,489 |

| LNC-120 | 155.9 | 50.8 | 47.6 | 2,499 | 5,370 | 409,125 | 4,616,551 |

| LNC-121 | 185.9 | 106.3 | 23.5 | 2,386 | 3,270 | 415,215 | 4,619,638 |

| LNC-122 | 112.8 | 14.2 | 50.2 | 2,769 | 4,480 | 408,183 | 4,616,581 |

| LNC-123 | 182.9 | 32.3 | 68.4 | 3,040 | 5,430 | 413,759 | 4,618,783 |

| LNC-124 | 61.6 | 2.9 | 16.7 | 2,108 | 4,180 | 408,157 | 4,616,747 |

| LNC-125 | 113.4 | 29.3 | 55.6 | 2,476 | 4,860 | 414,280 | 4,618,993 |

| LNC-126 | 193.6 | 11.4 | 88.9 | 2,614 | 5,230 | 410,275 | 4,616,421 |

| LNC-127 | 38.3 | 0.0 | 38.3 | 136 | 710 | 412,105 | 4,618,859 |

| LNC-128 | 218.9 | 94.5 | 60.1 | 2,884 | 5,430 | 410,604 | 4,616,218 |

| LNC-130 | 171.4 | 9.7 | 79.3 | 2,691 | 5,120 | 410,070 | 4,616,675 |

| LNC-131 | 88.8 | 14.1 | 53.2 | 2,867 | 4,070 | 411,572 | 4,618,921 |

| LNC-132 | 101.1 | 0.0 | 101.1 | 145 | 296 | 414,525 | 4,617,324 |

| LNC-133 | 93.2 | 21.3 | 52.1 | 2,986 | 6,660 | 410,706 | 4,618,942 |

| LNC-134 | 213.8 | 78.9 | 75.8 | 3,280 | 6,810 | 414,516 | 4,617,666 |

| LNC-135 | 111.4 | 7.6 | 71.3 | 2,877 | 4,720 | 411,013 | 4,618,878 |

| LNC-136 | 189.7 | 137.2 | 39.2 | 2,588 | 3,810 | 414,131 | 4,617,284 |

| LNC-137 | 72.8 | 6.7 | 54.0 | 2,819 | 4,620 | 411,249 | 4,619,054 |

| LNC-138 | 91.4 | 0.0 | 91.4 | 190 | 401 | 414,133 | 4,617,616 |

| LNC-139 | 76.5 | 9.9 | 56.6 | 2,851 | 5,220 | 411,215 | 4,618,908 |

| LNC-140 | 84.2 | 28.0 | 4.9 | 2,179 | 2,510 | 413,766 | 4,617,207 |

| LNC-141 | 105.0 | 8.8 | 70.1 | 3,165 | 5,730 | 411,301 | 4,618,718 |

| LNC-142 | 77.2 | 9.1 | 1.8 | 1,760 | 1,760 | 413,766 | 4,617,996 |

| LNC-143 | 77.5 | 17.3 | 6.3 | 1,764 | 2,380 | 414,548 | 4,618,065 |

| LNC-144 | 91.4 | 15.8 | 5.5 | 2,511 | 2,730 | 413,783 | 4,617,557 |

| WLC-001 | 125.0 | 6.1 | 41.1 | 2,896 | 4,700 | 410,991 | 4,617,491 |

| WLC-002 | 96.9 | 7.6 | 13.7 | 2,966 | 4,200 | 410,419 | 4,617,935 |

| WLC-003 | 185.3 | 4.6 | 77.7 | 2,914 | 7,100 | 412,247 | 4,617,934 |

| WLC-004 | 139.3 | 67.1 | 12.2 | 2,886 | 4,800 | 411,939 | 4,618,140 |

| WLC-005 | 182.9 | 16.8 | 80.8 | 2,664 | 6,000 | 412,139 | 4,617,635 |

| WLC-006 | 256.8 | 6.1 | 65.5 | 2,734 | 5,950 | 411,845 | 4,617,637 |

| WLC-007 | 188.1 | 6.1 | 59.4 | 2,274 | 4,428 | 411,535 | 4,617,635 |

| WLC-008 | 133.2 | 0.0 | 21.3 | 2,094 | 3,310 | 410,641 | 4,617,930 |

| WLC-009 | 96.6 | 6.1 | 3.0 | 2,291 | 2,719 | 410,938 | 4,617,933 |

| WLC-010 | 104.2 | 7.6 | 9.1 | 2,134 | 3,094 | 411,242 | 4,617,936 |

| WLC-011 | 100.3 | 51.8 | 24.4 | 1,981 | 3,500 | 411,234 | 4,617,630 |

| WLC-012 | 171.7 | 7.6 | 70.1 | 3,024 | 6,800 | 411,540 | 4,617,930 |

| WLC-013 | 126.9 | 7.6 | 62.5 | 2,919 | 6,500 | 411,835 | 4,617,934 |

| WLC-014 | 182.0 | 6.1 | 62.5 | 2,516 | 5,500 | 411,236 | 4,617,338 |

| WLC-015 | 139.4 | 6.1 | 30.3 | 2,346 | 4,300 | 410,946 | 4,617,640 |

| WLC-016 | 83.5 | 3.1 | 16.8 | 2,559 | 5,685 | 410,637 | 4,617,637 |

| WLC-017 | 274.9 | 63.7 | 70.4 | 2,496 | 4,577 | 410,831 | 4,617,134 |

| WLC-018 | 157.6 | 20.1 | 40.2 | 2,444 | 4,198 | 410,933 | 4,617,345 |

| WLC-019 | 105.8 | 15.2 | 90.5 | 20 | 184 | 410,339 | 4,617,638 |

| WLC-020 | 156.5 | 8.2 | 62.8 | 2,571 | 6,026 | 412,139 | 4,617,936 |

| WLC-021 | 152.4 | 9.1 | 53.3 | 2,493 | 4,508 | 412,046 | 4,617,944 |

| WLC-022 | 138.7 | 11.3 | 53.3 | 2,784 | 5,890 | 411,991 | 4,617,946 |

| WLC-023 | 130.2 | 11.3 | 65.8 | 2,750 | 5,500 | 411,890 | 4,618,034 |

| WLC-024 | 182.0 | 46.9 | 20.6 | 2,283 | 3,600 | 411,927 | 4,617,989 |

| WLC-025 | 159.1 | 6.7 | 68.5 | 2,757 | 6,800 | 411,896 | 4,617,941 |

| WLC-026 | 146.3 | 14.6 | 28.0 | 3,451 | 6,400 | 411,947 | 4,617,945 |

| WLC-027 | 115.8 | 11.3 | 59.2 | 2,926 | 6,230 | 412,009 | 4,617,890 |

| WLC-028 | 246.0 | 14.3 | 58.2 | 2,926 | 6,178 | 412,026 | 4,617,839 |

| WLC-029 | 122.8 | 12.2 | 51.8 | 2,182 | 4,200 | 412,047 | 4,617,790 |

| WLC-030 | 99.7 | 13.7 | 38.1 | 2,766 | 6,050 | 410,996 | 4,617,445 |

| WLC-031 | 93.6 | 5.2 | 34.1 | 2,349 | 3,890 | 410,993 | 4,617,564 |

| WLC-032 | 30.6 | 4.0 | 22.3 | 3,094 | 5,670 | 410,993 | 4,617,567 |

| WLC-033 | 30.5 | 4.0 | 25.3 | 3,054 | 5,782 | 410,988 | 4,617,446 |

| WLC-034 | 99.7 | 4.9 | 33.5 | 2,913 | 5,497 | 411,043 | 4,617,631 |

| WLC-035 | 121.9 | 4.6 | 27.7 | 2,743 | 5,859 | 411,142 | 4,617,639 |

| WLC-036 | 78.3 | 3.1 | 16.8 | 2,007 | 3,040 | 410,490 | 4,617,938 |

| WLC-037 | 69.2 | 3.1 | 16.8 | 2,105 | 3,023 | 410,569 | 4,617,939 |

| WLC-040 | 79.8 | 9.5 | 38.8 | 3,308 | 6,720 | 411,772 | 4,618,186 |

| WLC-041 | 56.3 | 9.8 | 38.6 | 3,367 | 6,170 | 411,541 | 4,618,122 |

| WLC-042 | 91.7 | 5.6 | 54.8 | 3,244 | 6,840 | 411,424 | 4,617,786 |

| WLC-043 | 86.0 | 4.6 | 57.8 | 3,433 | 7,080 | 411,684 | 4,618,053 |

| WLC-044 | 116.4 | 8.3 | 73.3 | 3,096 | 6,960 | 411,690 | 4,617,802 |

| WLC-045 | 107.2 | 4.7 | 67.8 | 2,879 | 6,270 | 411,882 | 4,617,800 |

| WLC-046 | 116.4 | 0.0 | 70.2 | 2,853 | 6,480 | 411,368 | 4,617,543 |

| WLC-047 | 107.3 | 6.2 | 73.6 | 3,116 | 7,260 | 411,671 | 4,617,536 |

| WLC-048 | 122.6 | 15.8 | 73.3 | 3,025 | 6,330 | 411,827 | 4,617,478 |

| WLC-049 | 115.5 | 9.7 | 75.2 | 3,136 | 5,960 | 411,979 | 4,617,539 |

| WLC-050 | 154.6 | 36.6 | 79.6 | 2,926 | 6,700 | 412,037 | 4,617,357 |

| WLC-051 | 136.3 | 36.6 | 56.0 | 2,592 | 5,150 | 412,294 | 4,618,115 |

| WLC-052 | 126.2 | 17.4 | 68.0 | 2,985 | 7,710 | 412,109 | 4,618,123 |

| WLC-053 | 121.1 | 24.1 | 79.5 | 3,014 | 6,350 | 412,478 | 4,617,805 |

| WLC-054 | 87.5 | 9.4 | 20.4 | 2,605 | 4,620 | 412,427 | 4,617,977 |

| WLC-055 | 124.1 | 23.5 | 77.6 | 2,823 | 6,140 | 412,311 | 4,617,718 |

| WLC-056 | 139.4 | 35.7 | 75.7 | 2,892 | 6,400 | 412,289 | 4,617,535 |

| WLC-057 | 273.5 | 11.1 | 91.4 | 2,978 | 7,570 | 412,820 | 4,617,622 |

| WLC-058 | 737.0 | 7.2 | 100.6 | 2,739 | 5,690 | 412,229 | 4,617,131 |

| WLC-059 | 142.4 | 7.0 | 79.5 | 2,903 | 7,220 | 412,460 | 4,617,617 |

| WLC-060 | 145.5 | 22.9 | 71.6 | 2,787 | 7,030 | 412,461 | 4,617,437 |

| WLC-061 | 157.6 | 8.3 | 82.6 | 2,810 | 6,420 | 412,286 | 4,617,360 |

| WLC-062 | 63.9 | 8.3 | 49.2 | 3,617 | 7,550 | 411,389 | 4,617,985 |

| WLC-063 | 91.6 | 3.1 | 66.3 | 3,263 | 6,920 | 411,358 | 4,618,181 |

| WLC-064 | 114.9 | 13.9 | 66.7 | 3,172 | 6,120 | 411,334 | 4,618,372 |

| WLC-065 | 108.8 | 20.5 | 72.3 | 3,260 | 6,380 | 411,183 | 4,618,104 |

| WLC-066 | 82.9 | 3.7 | 63.2 | 3,050 | 5,880 | 411,198 | 4,618,286 |

| WLC-067 | 108.2 | 14.3 | 70.9 | 2,922 | 6,290 | 410,748 | 4,618,141 |

| WLC-068 | 132.4 | 28.5 | 66.1 | 2,665 | 5,340 | 411,195 | 4,617,490 |

| WLC-069 | 136.3 | 26.7 | 73.1 | 2,964 | 6,990 | 411,506 | 4,617,450 |

| WLC-070 | 153.8 | 2.6 | 79.5 | 2,788 | 6,660 | 411,692 | 4,617,352 |

| WLC-071 | 130.2 | 4.1 | 74.7 | 3,074 | 6,380 | 411,781 | 4,618,383 |

| WLC-072 | 145.4 | 74.4 | 46.3 | 3,112 | 6,080 | 411,939 | 4,618,326 |

| WLC-073 | 151.4 | 43.7 | 59.0 | 2,865 | 5,840 | 412,122 | 4,618,495 |

| WLC-074 | 106.1 | 35.7 | 2.9 | 1,765 | 2,080 | 412,432 | 4,618,339 |

| WLC-075 | 96.0 | 9.5 | 64.0 | 3,015 | 5,820 | 411,138 | 4,618,434 |

| WLC-076 | 125.6 | 4.8 | 70.9 | 2,914 | 5,030 | 410,969 | 4,618,483 |

| WLC-077 | 122.6 | 4.3 | 73.6 | 2,941 | 5,820 | 411,243 | 4,618,580 |

| WLC-078 | 90.1 | 12.0 | 68.4 | 3,112 | 7,030 | 411,010 | 4,618,306 |

| WLC-079 | 131.7 | 11.8 | 72.3 | 3,051 | 6,480 | 411,377 | 4,618,547 |

| WLC-080 | 113.5 | 2.3 | 69.4 | 2,923 | 4,850 | 411,063 | 4,618,643 |

| WLC-081 | 90.0 | 11.0 | 59.1 | 3,350 | 6,070 | 410,980 | 4,618,129 |

| WLC-082 | 98.1 | 23.2 | 61.8 | 3,322 | 6,920 | 410,639 | 4,618,298 |

| WLC-083 | 136.3 | 8.2 | 80.0 | 3,005 | 6,560 | 410,428 | 4,618,488 |

| WLC-084 | 89.1 | 12.0 | 59.0 | 3,073 | 5,710 | 410,825 | 4,618,291 |

| WLC-085 | 61.2 | 6.7 | 47.2 | 3,498 | 6,690 | 410,054 | 4,618,498 |

| WLC-086 | 102.7 | 26.5 | 62.0 | 3,291 | 7,090 | 410,430 | 4,618,304 |

| WLC-087 | 134.1 | 21.6 | 71.2 | 3,134 | 5,700 | 410,414 | 4,618,660 |

| WLC-088 | 125.1 | 6.5 | 76.0 | 3,077 | 5,630 | 410,591 | 4,618,480 |

| WLC-089 | 142.4 | 35.5 | 67.3 | 2,850 | 4,730 | 410,601 | 4,618,635 |

| WLC-090 | 105.8 | 6.8 | 69.8 | 2,956 | 7,120 | 410,773 | 4,618,470 |

| WLC-091 | 123.7 | 9.8 | 69.4 | 3,026 | 5,550 | 410,868 | 4,618,635 |

| WLC-092 | 97.5 | 8.2 | 74.3 | 3,020 | 6,690 | 410,587 | 4,618,089 |

| WLC-093 | 57.0 | 3.2 | 20.4 | 2,732 | 5,510 | 411,178 | 4,617,786 |

| WLC-094 | 43.3 | 3.2 | 21.7 | 2,469 | 4,450 | 410,998 | 4,617,786 |

| WLC-095 | 70.0 | 5.2 | 54.7 | 3,672 | 6,850 | 411,375 | 4,617,935 |

| WLC-096 | 119.5 | 18.5 | 77.9 | 3,024 | 6,680 | 411,201 | 4,618,049 |

| WLC-097 | 67.7 | 5.6 | 49.2 | 3,114 | 5,950 | 411,366 | 4,618,107 |

| WLC-098 | 89.0 | 9.9 | 65.7 | 3,178 | 6,850 | 411,189 | 4,618,230 |

| WLC-099 | 71.8 | 6.1 | 49.3 | 2,808 | 5,960 | 411,323 | 4,618,052 |

| WLC-100 | 67.7 | 7.6 | 46.4 | 3,454 | 6,270 | 411,438 | 4,618,056 |

| WLC-101 | 117.9 | 21.0 | 76.2 | 3,118 | 7,060 | 411,252 | 4,618,110 |

| WLC-102 | 69.2 | 7.8 | 53.3 | 3,127 | 6,260 | 411,371 | 4,617,876 |

| WLC-103 | 90.5 | 15.2 | 63.3 | 3,436 | 6,990 | 411,071 | 4,618,110 |

| WLC-104 | 75.3 | 5.7 | 53.7 | 3,185 | 6,350 | 411,370 | 4,617,811 |

| WLC-105 | 98.2 | 16.6 | 66.5 | 3,392 | 7,640 | 411,135 | 4,618,168 |

| WLC-106 | 72.8 | 9.4 | 55.6 | 3,235 | 6,940 | 411,133 | 4,618,231 |

| WLC-107 | 89.0 | 6.0 | 64.3 | 3,377 | 6,240 | 411,135 | 4,618,288 |

| WLC-108 | 103.2 | 16.0 | 68.8 | 3,291 | 6,970 | 411,133 | 4,618,112 |

| WLC-109 | 82.9 | 3.1 | 66.5 | 3,274 | 6,150 | 411,310 | 4,618,291 |

| WLC-110 | 119.5 | 17.2 | 71.2 | 3,164 | 6,870 | 411,137 | 4,618,049 |

| WLC-111 | 73.8 | 4.9 | 57.2 | 3,219 | 6,880 | 411,312 | 4,618,232 |

| WLC-112 | 57.0 | 5.6 | 38.5 | 3,556 | 7,420 | 411,189 | 4,617,991 |

| WLC-113 | 77.7 | 8.7 | 62.1 | 3,510 | 6,780 | 411,378 | 4,618,228 |

| WLC-114 | 60.1 | 5.3 | 47.2 | 3,727 | 7,030 | 411,249 | 4,617,989 |

| WLC-115 | 85.3 | 7.4 | 67.0 | 3,303 | 7,710 | 411,312 | 4,618,167 |

| WLC-116 | 101.1 | 11.4 | 69.8 | 3,220 | 7,230 | 411,315 | 4,618,109 |

| WLC-117 | 61.6 | 5.3 | 50.5 | 3,435 | 7,240 | 411,313 | 4,617,992 |

| WLC-118 | 40.3 | 3.8 | 28.9 | 3,937 | 8,690 | 411,308 | 4,617,931 |

| WLC-119 | 27.7 | 4.1 | 16.5 | 2,732 | 4,400 | 411,189 | 4,617,931 |

| WLC-120 | 25.0 | 2.5 | 14.7 | 3,338 | 4,940 | 411,125 | 4,617,932 |

| WLC-121 | 22.0 | 1.7 | 11.6 | 3,345 | 4,600 | 411,073 | 4,617,936 |

| WLC-122 | 34.1 | 2.0 | 16.4 | 2,666 | 4,730 | 411,250 | 4,617,877 |

| WLC-123 | 58.6 | 8.2 | 39.7 | 3,586 | 6,370 | 411,439 | 4,618,119 |

| WLC-124 | 57.0 | 11.3 | 38.8 | 3,862 | 7,380 | 411,440 | 4,618,166 |

| WLC-125 | 46.4 | 0.3 | 37.0 | 3,324 | 8,540 | 411,075 | 4,617,991 |

| WLC-126 | 58.6 | 5.4 | 45.5 | 3,406 | 5,370 | 411,503 | 4,618,160 |

| WLC-127 | 49.4 | 1.5 | 40.6 | 3,644 | 6,970 | 411,010 | 4,617,990 |

| WLC-128 | 61.6 | 6.7 | 43.3 | 3,685 | 6,150 | 411,499 | 4,618,112 |

| WLC-129 | 90.7 | 10.6 | 65.5 | 3,251 | 7,250 | 411,008 | 4,618,047 |

| WLC-130 | 61.6 | 7.8 | 49.1 | 3,665 | 6,670 | 411,501 | 4,618,056 |

| WLC-131 | 99.6 | 18.4 | 67.1 | 3,205 | 6,590 | 411,074 | 4,618,048 |

| WLC-132 | 69.2 | 9.4 | 50.8 | 3,426 | 6,110 | 411,495 | 4,617,998 |

| WLC-133 | 69.2 | 5.6 | 50.4 | 3,839 | 6,390 | 411,437 | 4,617,984 |

| WLC-134 | 76.9 | 6.2 | 62.4 | 3,651 | 7,200 | 411,440 | 4,617,930 |

| WLC-135 | 81.4 | 8.2 | 59.4 | 3,183 | 6,800 | 411,502 | 4,617,934 |

| WLC-136 | 38.4 | 2.3 | 30.1 | 3,232 | 6,720 | 411,132 | 4,617,987 |

| WLC-137 | 90.6 | 12.0 | 65.6 | 3,462 | 7,080 | 411,017 | 4,618,113 |

| WLC-138 | 64.7 | 8.5 | 50.0 | 3,419 | 7,400 | 411,440 | 4,617,872 |

| WLC-139 | 99.7 | 19.9 | 62.2 | 3,436 | 7,670 | 411,078 | 4,618,167 |

| WLC-140 | 92.1 | 9.7 | 66.7 | 3,403 | 8,850 | 411,494 | 4,617,875 |

| WLC-141 | 72.2 | 6.7 | 57.7 | 3,517 | 6,820 | 411,567 | 4,617,993 |

| WLC-142 | 92.0 | 19.3 | 62.8 | 3,505 | 6,710 | 411,019 | 4,618,166 |

| WLC-143 | 67.7 | 6.9 | 48.0 | 3,329 | 6,200 | 411,566 | 4,618,050 |

| WLC-144 | 96.6 | 15.8 | 69.8 | 3,431 | 7,390 | 411,074 | 4,618,228 |

| WLC-145 | 88.9 | 6.5 | 66.5 | 3,389 | 6,240 | 411,127 | 4,618,401 |

| WLC-146 | 93.6 | 14.6 | 64.5 | 3,137 | 6,580 | 411,009 | 4,618,230 |

| WLC-147 | 87.2 | 10.5 | 63.7 | 3,056 | 6,540 | 411,074 | 4,618,413 |

| WLC-148 | 89.6 | 9.8 | 67.4 | 3,361 | 7,230 | 411,074 | 4,618,290 |

| WLC-149 | 88.9 | 13.1 | 60.7 | 3,274 | 6,350 | 411,016 | 4,618,420 |

| WLC-150 | 78.4 | 2.8 | 57.9 | 3,461 | 7,150 | 411,131 | 4,618,354 |

| WLC-151 | 92.1 | 9.3 | 68.9 | 3,279 | 7,780 | 411,071 | 4,618,361 |

| WLC-152 | 55.8 | 7.8 | 37.7 | 3,840 | 6,970 | 411,563 | 4,618,119 |

| WLC-153 | 88.1 | 9.8 | 67.8 | 3,378 | 6,680 | 411,009 | 4,618,362 |

| WLC-154 | 51.0 | 10.4 | 33.8 | 3,542 | 6,040 | 411,619 | 4,618,108 |

| WLC-155 | 67.7 | 5.2 | 53.9 | 3,354 | 6,630 | 411,622 | 4,618,058 |

| WLC-156 | 61.0 | 4.7 | 46.4 | 2,960 | 6,240 | 411,690 | 4,618,112 |

| WLC-157 | 40.2 | 3.7 | 21.5 | 3,394 | 6,030 | 411,319 | 4,617,869 |

| WLC-158 | 55.4 | 5.9 | 43.7 | 3,658 | 6,860 | 411,564 | 4,618,155 |

| WLC-159 | 76.8 | 7.7 | 59.2 | 3,317 | 5,900 | 411,749 | 4,618,048 |

| WLC-160 | 70.8 | 9.5 | 53.4 | 3,317 | 7,090 | 411,761 | 4,618,109 |

| WLC-161 | 82.9 | 6.3 | 57.2 | 3,167 | 7,010 | 411,814 | 4,618,050 |

| WLC-162 | 71.2 | 9.8 | 49.8 | 3,380 | 7,430 | 411,813 | 4,618,105 |

| WLC-163 | 86.0 | 9.1 | 63.6 | 3,362 | 6,610 | 411,746 | 4,617,928 |

| WLC-164 | 104.2 | 9.9 | 61.4 | 3,165 | 7,260 | 411,875 | 4,617,990 |

| WLC-165 | 70.7 | 5.5 | 61.1 | 3,224 | 7,390 | 411,748 | 4,617,868 |

| WLC-166 | 89.0 | 9.4 | 58.5 | 3,164 | 6,360 | 411,811 | 4,617,999 |

| WLC-167 | 104.3 | 8.1 | 73.9 | 3,296 | 8,360 | 411,748 | 4,617,802 |

| WLC-168 | 87.5 | 4.6 | 64.7 | 3,139 | 6,870 | 411,746 | 4,617,990 |

| WLC-169 | 104.3 | 7.7 | 75.4 | 3,229 | 7,600 | 411,749 | 4,617,748 |

| WLC-170 | 79.9 | 9.1 | 55.9 | 3,326 | 7,140 | 411,685 | 4,617,986 |

| WLC-171 | 95.2 | 9.0 | 70.5 | 3,328 | 7,850 | 411,685 | 4,617,744 |

| WLC-172 | 92.1 | 4.9 | 72.2 | 3,086 | 7,470 | 411,686 | 4,617,869 |

| WLC-173 | 75.3 | 5.2 | 56.4 | 3,505 | 6,190 | 411,622 | 4,617,996 |

| WLC-174 | 83.0 | 6.6 | 59.6 | 3,379 | 8,070 | 411,690 | 4,617,929 |

| WLC-175 | 86.0 | 6.7 | 59.0 | 3,362 | 7,230 | 411,497 | 4,617,743 |

| WLC-176 | 82.9 | 6.7 | 65.9 | 3,258 | 6,910 | 411,629 | 4,617,933 |

| WLC-177 | 88.8 | 5.3 | 71.2 | 3,292 | 6,900 | 411,501 | 4,617,814 |

| WLC-178 | 87.5 | 4.5 | 73.9 | 3,065 | 6,730 | 411,627 | 4,617,875 |

| WLC-179 | 92.1 | 11.7 | 64.9 | 3,413 | 6,980 | 411,620 | 4,617,808 |

| WLC-180 | 140.9 | 7.6 | 79.7 | 3,206 | 6,260 | 413,412 | 4,617,807 |

| WLC-181 | 30.7 | 19.0 | 1.5 | 1,570 | 1,570 | 412,811 | 4,618,200 |

| WLC-182 | 30.5 | 23.3 | 7.2 | 418 | 660 | 412,818 | 4,618,546 |

| WLC-183 | 30.5 | 17.8 | 7.1 | 1,992 | 2,350 | 413,414 | 4,617,430 |

| WLC-184 | 37.2 | 13.4 | 7.5 | 2,288 | 2,670 | 411,443 | 4,617,292 |

| WLC-185 | 95.0 | 30.2 | 1.1 | 1,740 | 1,740 | 413,407 | 4,618,532 |

| WLC-186 | 86.0 | 2.1 | 62.0 | 3,253 | 7,760 | 411,253 | 4,618,319 |

| WLC-187 | 101.3 | 8.0 | 59.9 | 3,349 | 7,080 | 411,554 | 4,617,742 |

| WLC-188 | 63.2 | 8.8 | 47.8 | 3,565 | 6,810 | 411,435 | 4,618,220 |

| WLC-189 | 97.0 | 9.6 | 69.9 | 3,267 | 7,070 | 411,561 | 4,617,808 |

| WLC-190 | 74.5 | 5.1 | 59.0 | 3,281 | 6,130 | 411,192 | 4,618,354 |

| WLC-191 | 98.2 | 5.8 | 68.1 | 3,369 | 7,300 | 411,558 | 4,617,864 |

| WLC-192 | 92.1 | 7.8 | 61.1 | 3,229 | 6,200 | 411,251 | 4,618,229 |

| WLC-193 | 104.3 | 12.2 | 69.8 | 3,200 | 7,200 | 411,617 | 4,617,751 |

| WLC-194 | 110.3 | 12.1 | 69.3 | 3,491 | 7,730 | 411,250 | 4,618,170 |

| WLC-195 | 70.7 | 5.8 | 44.9 | 3,559 | 7,380 | 411,363 | 4,618,053 |

| WLC-196 | 116.4 | 14.7 | 72.1 | 3,470 | 7,270 | 411,180 | 4,618,169 |

| WLC-197 | 92.4 | 3.5 | 62.6 | 3,200 | 6,790 | 410,397 | 4,618,123 |

| WLC-198 | 79.8 | 13.8 | 45.8 | 3,155 | 6,480 | 411,247 | 4,618,045 |

| WLC-199 | 115.7 | 15.9 | 69.9 | 3,381 | 8,160 | 410,412 | 4,618,187 |

| WLC-200 | 73.8 | 2.3 | 29.0 | 3,476 | 6,670 | 410,649 | 4,617,482 |

| WLC-201 | 61.6 | 2.8 | 42.1 | 3,373 | 6,120 | 409,939 | 4,618,572 |

| WLC-202 | 61.6 | 8.9 | 31.6 | 3,869 | 7,250 | 409,614 | 4,618,640 |

| WLC-203 | 131.5 | 11.5 | 63.0 | 3,235 | 7,010 | 410,242 | 4,618,324 |

| WLC-204 | 113.0 | 0.0 | 76.5 | 3,020 | 6,550 | 410,283 | 4,618,187 |

| WLC-205 | 124.1 | 18.2 | 64.3 | 3,156 | 6,700 | 410,096 | 4,618,649 |

| WLC-206 | 104.2 | 3.5 | 63.5 | 3,037 | 5,640 | 410,237 | 4,618,667 |

| WLC-207 | 123.6 | 31.5 | 72.3 | 3,309 | 6,940 | 410,251 | 4,618,509 |

| WLC-208 | 69.2 | 14.2 | 30.5 | 3,687 | 6,190 | 409,762 | 4,618,613 |

| WLC-209 | 18.4 | 4.9 | 7.2 | 2,864 | 3,650 | 412,299 | 4,617,945 |

| WLC-210 | 18.3 | 5.2 | 6.4 | 2,564 | 3,860 | 412,282 | 4,617,941 |

| WLC-211 | 18.3 | 4.3 | 5.2 | 2,855 | 3,320 | 412,267 | 4,617,938 |

| WLC-212 | 18.3 | 5.2 | 5.5 | 2,679 | 3,720 | 412,237 | 4,617,932 |

| WLC-213 | 18.4 | 8.5 | 4.1 | 2,685 | 2,980 | 412,222 | 4,617,928 |

| WLC-214 | 18.3 | 10.5 | 4.4 | 2,669 | 2,960 | 412,207 | 4,617,926 |

| WLC-215 | 18.3 | 13.3 | 2.0 | 2,782 | 3,070 | 411,997 | 4,617,901 |

| WLC-218 | 18.3 | 6.7 | 1.5 | 2,718 | 2,820 | 411,440 | 4,617,857 |

| WLC-219 | 18.3 | 6.7 | 1.5 | 2,860 | 2,860 | 411,439 | 4,617,888 |

| WLC-220 | 18.3 | 8.8 | 2.4 | 3,161 | 3,700 | 411,439 | 4,617,903 |

| WLC-221 | 18.3 | 8.8 | 2.7 | 2,679 | 2,690 | 411,440 | 4,617,916 |

| WLC-222 | 18.3 | 9.8 | 2.1 | 3,038 | 3,300 | 411,458 | 4,617,932 |

| WLC-223 | 18.3 | 6.7 | 3.2 | 2,622 | 2,900 | 411,473 | 4,617,932 |

| WLC-224 | 18.3 | 8.5 | 1.4 | 2,870 | 2,920 | 411,486 | 4,617,933 |

| WLC-225 | 18.3 | 7.0 | 4.6 | 2,286 | 2,580 | 411,493 | 4,617,860 |

| WLC-226 | 18.3 | 7.3 | 2.3 | 2,709 | 2,760 | 411,497 | 4,617,889 |

| WLC-227 | 18.3 | 8.2 | 4.0 | 2,820 | 2,940 | 411,498 | 4,617,904 |

| WLC-228 | 18.3 | 8.2 | 4.3 | 2,885 | 3,320 | 411,500 | 4,617,918 |

| WLC-229 | 18.3 | 8.2 | 2.3 | 2,884 | 3,370 | 411,517 | 4,617,934 |

| WLC-230 | 18.3 | 9.5 | 1.8 | 3,310 | 3,590 | 411,543 | 4,617,915 |

| WLC-231 | 18.3 | 11.3 | 3.4 | 2,976 | 3,180 | 411,547 | 4,617,899 |

| WLC-232 | 18.3 | 6.1 | 2.9 | 2,929 | 3,680 | 411,554 | 4,617,880 |

Notes:

- Holes drilled but not assayed include: LNC-049 through LNC-056, LNC-086, LNC-129, WLC-038, WLC-039, WLC-216, WLC-217. These holes were assigned null values and therefore not used in the Mineral Resource estimation.

- Holes with no intercepts above the cut-off grade of 1,334 ppm Li were primarily drilled into volcanic rock. These holes are used in the Mineral Resource estimation: LNC-005, LNC-006, LNC-007, LNC-095, LNC-103, LNC-110, LNC-119, LNC-127, LNC-132, LNC-138, WLC-019, and WLC-182.

- Holes removed from use in estimation due to twinned drilling include: LNC-002, LNC-012, LNC-110, LNC-081, WLC-040, WLC-076 and WLC-183.

- All holes except WLC-058 and LNC-083 are drilled vertically (WLC-058 Az:180º Dip:-70º, LNC-083 Az:180º Dip:-60º)

- The resource mineralization is sub-horizontal and interval thickness represent true thickness.

- Average Lithium grades shown represent true averages with no high-grade nugget or vein effect from short high grade intervals.