Forsys Reports Updated Mineral Resource Estimate for its Norasa Project in Namibia

TORONTO, May 14, 2024 (GLOBE NEWSWIRE) -- Forsys Metals Corp. (TSX: FSY) (FSE: F2T) (NSX: FSY) (“Forsys” or the “Company”)

Forsys is pleased to provide an update for the Company’s Norasa Uranium project (“Norasa1”) which comprises the deposits of Valencia Main and East, (“Valencia”), under Mining Licence (ML-149) and Namibplaas (“Namibplaas”) under EPL-3638, (ML-251 pending).

Highlights

Forsys has undertaken a comprehensive review and update of all of the parameters for a Mineral Resource Estimate (“MRE”) for the Norasa project using recent drill results together with the 2005-2011 previous MRE data. Confirmatory and geotechnical drilling, in conjunction with new survey information, including topographic surveys, down-the-hole optical televiewer surveys, trajectory surveys, and downhole gamma probe surveys, were used as inputs for mineral resource modelling. Re-interpretation of the previous database utilising all available data and modern estimation approaches has improved the definition of the MRE to more confidently support mine planning. This study, enhanced by an integrated and expanded drill program targeting existing and new areas together with a robust work plan of optimisation process testing and modelling, will help reinforce the upside potential of the Norasa project.

- For the overall Norasa project, a conceptual pit constrained MRE for total deposits assessed from previous (2005-2011) and 2023 drilling results is estimated to be:

- Valencia Main Measured and Indicated Resource at 40 ppm U3O8 cutoff is estimated to be 152 Mt at 136 ppm eU3O8 (equivalent U3O8). Measured and Indicated contained metal is estimated at 45 Mlbs U3O8, at 40 ppm U3O8 cutoff.

- Valencia Main and East Inferred Resources are estimated at 5.7 Mt at 120 ppm eU3O8 with 1.3 Mlbs U3O8 contained metal oxide, at 40 ppm U3O8 cutoff.

- Namibplaas Inferred Resources are estimated to be 218.7 Mt at 85 ppm eU3O8 with 41.1 Mlbs U3O8 contained metal oxide, at 40 ppm U3O8 cutoff.

Pine van Wyk, Country Director for Forsys commented: “The comprehensive work done over the last twelve months on the Norasa Uranium Project has created a solid foundation to advance project development. The revised mineral resource model will help optimise the mine economics and process parameters. Results are expected soon from a column leaching test program currently being undertaken at SGS Laboratories in South Africa, which would establish the design basis of the planned heap leaching pads. With the existing ML149 permitted to commence mining, the large scale Norasa project is well advanced to take advantage of the strong uranium sector fundamentals.”

Mineral Resources

Results are reported from recent remodelling of historical (2005-2011) drilling and recent 2023 drilling results. The Mineral Resources are reported within US$120/lb U3O8 pit shells, with a cut-off grade of 40 ppm U3O8 for each of the deposits at Valencia Main and East, (“Valencia”), under Mining Licence (ML-149) and US$120/lb U3O8 at 40 ppm U3O8 cutoff at Namibplaas (“Namibplaas”) under EPL-3638. The MRE are summarised as follows:

For the overall Norasa project, a conceptual open-pit shell constrained MRE for total deposits assessed from previous (2005-2011) and recent (2023) drilling results is estimated to be Measured and Indicated of 151.9 Mt at 136 ppm eU3O8, with contained metal oxide of 45.4 Mlbs U3O8 at Valencia Main. Inferred Resources for the Norasa project are estimated to be 224.5 Mt at 86 ppm eU3O8, with contained metal oxide of 42.6 Mlbs U3O8 (refer to Table 1):

- Measured and Indicated: 151.9 Mt at 136ppm eU3O8, with contained metal oxide of 45.4 Mlbs for Valencia Main.

- Inferred Resource for Valencia Main is estimated to be 4.7 Mt at 121 ppm eU3O8 and 1.3 Mlbs eU3O8 contained metal oxide.

- Inferred Resource for Valencia East is estimated to be 1.0 Mt at 114 ppm eU3O8 and 0.3 Mlbs U3O8 contained metal oxide; and

- Inferred Resource for Namibplaas is estimated to be 218.7 Mt at 85 ppm eU3O8 and 41.1 Mlbs U3O8 contained metal oxide.

Table 1: Mineral Resource Estimate for Norasa project as at 30 April 2024 at a 40 ppm U3O8 cut-off grade.

| Class | Deposit | Mass Mt (metric) | Average Grade eU3O8 (ppm) | Material Content U3O8 Mlbs | Contained Metal U tonnes | |

| Measured | Valencia East | |||||

| Valencia Main | 7.6 | 171 | 2.9 | 1,099 | ||

| Namibplaas | ||||||

| Norasa | 7.6 | 171 | 2.9 | 1,099 | ||

| Indicated | Valencia East | |||||

| Valencia Main | 144.3 | 134 | 42.6 | 16,368 | ||

| Namibplaas | ||||||

| Norasa | 144.3 | 134 | 42.6 | 16,368 | ||

| Measured & Indicated | Valencia East | |||||

| Valencia Main | 151.9 | 136 | 45.4 | 17,467 | ||

| Namibplaas | ||||||

| Norasa | 151.9 | 136 | 45.4 | 17,467 | ||

| Inferred | Valencia East | 1.0 | 114 | 0.3 | 97 | |

| Valencia Main | 4.7 | 121 | 1.3 | 487 | ||

| Namibplaas | 218.7 | 85 | 41.1 | 15,817 | ||

| Norasa | 224.5 | 86 | 42.6 | 16,401 |

| Notes: | |

| 1. | All tabulated data have been rounded and as a result minor computational errors may occur. |

| 2. | Mineral Resources, which are not Mineral Reserves, have no demonstrated economic viability. There is no guarantee that all or any part of the mineral resource will be converted into a mineral reserve. The estimate of mineral resources may be materially affected by geology, environment, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues. |

| 3. | The Mineral Resource Statement for Norasa as at 30th April 2024 is reported at a cut-off grade of 40ppm U3O8 from within a conceptual pit-shell using the following assumed parameters:

|

| 4. | From the assumed parameters, a 40 ppm U3O8 cut-off grade was calculated, which together with the conceptual pit shell demonstrates reasonable prospects for eventual economic extraction (RPEEE) for the Mineral Resource. The assessment to satisfy the criteria of RPEEE is a high-level estimate and is not an attempt to estimate Mineral Reserves. |

Mineral Resource Estimation Methodology

A summary of the Mineral Resource modelling methodology is as follows:

- The Mineral Resource was modelled using a combination of Leapfrog Geo® and Datamine Studio RM® software.

- Valencia Main and East data:

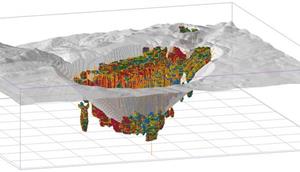

- Comprise a combined dataset of 141 diamond (DD), 148 reverse circulation (RC) and 446 percussion (PC) type drill holes (Figure 1).

- Borehole data from Valencia Main and East with XRF assay and calculated equivalent grades (eU3O8) from gamma-probing for each of the deposits have been used to estimate the Mineral Resource.

- Equivalent uranium grades have been factored to correlate practically well with the XRF data, which constitutes 25 % of the grade data.

- Where XRF data are available these supercede the corresponding probe equivalent grade in the estimation data.

- Namibplaas data:

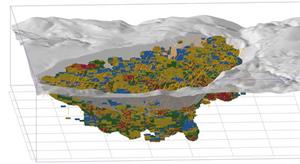

- Comprise a dataset of 530 percussion holes and 40 diamond drill holes (Figure 2).

- Borehole data from Namibplaas XRF assay and calculated equivalent grades (eU3O8) have been used to estimate the Inferred Mineral Resource.

- Equivalent uranium grades constitute the majority of the grade data and where XRF data are available, ~3.5 % of all grade data, these supercede the probe derived values.

- Wireframe interpretations of the logged lithologies were used to define the various geological units.

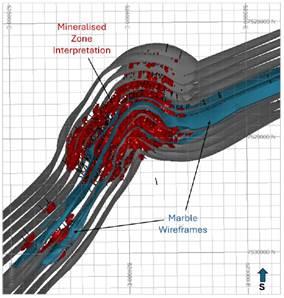

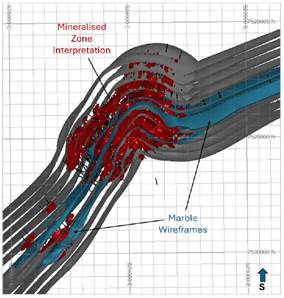

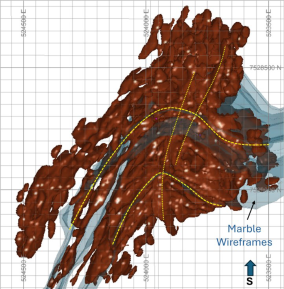

- Mineralisation is strongly associated with alaskite intrusions, that are in turn controlled by a structural architecture that comprises folded and planar strata surfaces, and fold-associated shears and cleavages. Importantly, the orientation of marble strata is a major control on the distribution of uranium mineralisation for REDOX chemistry reasons, at Valencia and the Erongo region alaskite deposits as whole. The alaskite orientations are therefore strataform, except where they have invaded sheared and strongly cleaved antiformal hinge zones, as at Valencia Main. In order to honour the geological controls in the estimates various surfaces were modelled:

- String interpretations of the “stratiform” intrusions were digitised in cross-section and were used to create median surfaces for each of the intrusions.

- The resulting mineralised zone wireframes align with the lithological strata while also cross-cutting the strata in places to accommodate axial-planar mineralisation orientations (see Figure 3).

- The surfaces were then used to guide the orientation of the grade estimate through interpolation of individual dip and dip directions for each model block.

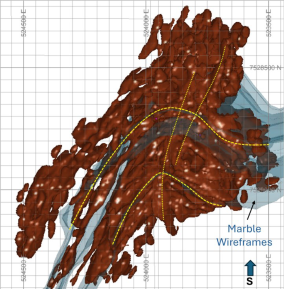

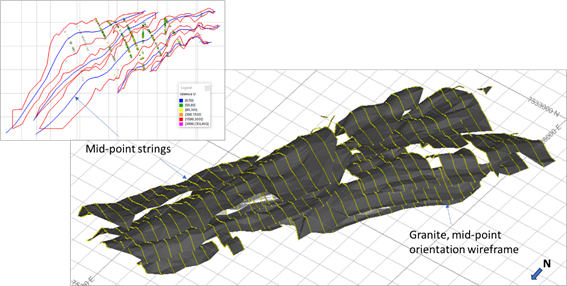

- The geometry of the Namibplaas deposit comprises stratiform lithologies that dip toward the southwest. The alaskite intrusives have intruded in a strataform manner and have exploited disruptions in the overall fabric, such as local fold flexures and dilation zones associated with the NE-SW regional extensional setting. In order to honour the geological controls at Namibplaas in the estimates various surfaces were modelled with guidance from the directions of greatest structural continuity to guide implicit modelling:

- Along the strike and dip direction of the host metasediments, and

- Along a shallow-plunging hinge structure that is oriented to the NE, parallel to the regional extension regime.

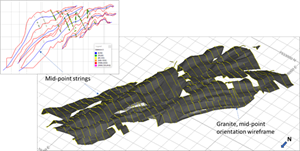

- Considering that mineralization at Namibplaas is strongly associated with the granitic intrusions, string interpretations of the mid-points of these “stratiform” intrusions were digitized in cross-section, thereafter linked to create median surfaces of each of the alaskite intrusions (see Figure 4).

- The surfaces of the intrusions were then used to guide the orientation of the grade estimate through interpolation of individual dip and dip directions for each model block.

- Grade shells using a 40 ppm U3O8 threshold were constructed using Leapfrog® implicit modelling with directional control surfaces from the geological model.

- The model volumes were divided into four domains at Valencia Main and two domains at Namibplaas. Each domain is distinct in terms of its geographic/geometric position as well as statistical / geostatistical parameters.

- Ordinary kriging estimation used three-dimensional directional variograms to estimate U3O8 grades within the mineralised zones for Valencia Main and Namibplaas. Inverse distance squared interpolation was used for Valancia East. The models underwent validation by comparison of estimated grade values against input sample grades, both visually and statistically.

- Volumes covered by 30 m drill-spacing were classified as Indicated Mineral Resources at Valencia. All blocks outside of these volumes within the grade shells that received a grade estimate during the interpolation runs were considered Inferred.

- At Namibplaas, although the tight drill spacing of approximately 30 m provides dense coverage of the deposit, the predominance of probe-derived eU3O8 assays warrants a confidence level for an Inferred Resource.

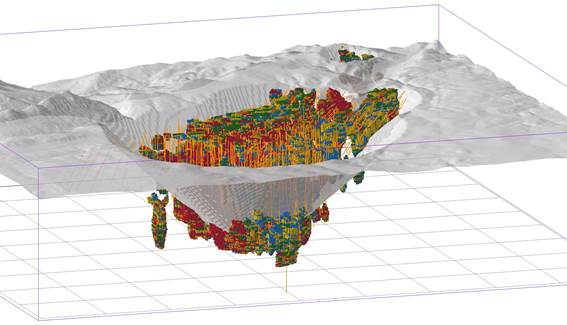

Figure 1: 30 April 2024 MRE block model and US$120/lb U3O8 pit shells at Valencia Main and Valencia East, ML 149.

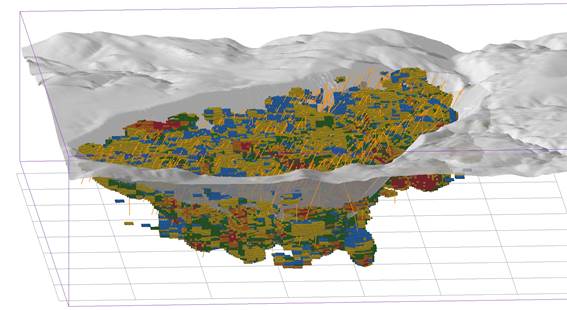

Figure 2: 30 April 2024 MRE block model and US$120/lb U3O8 pit shells at Namibplaas, EPL 3638.

Figure 3: Shows the stacked concordant surfaces generated parallel to the 3 marble bands and orientation of mineralisation aligned with the strata and axial planar cleavages in the fold hinge (guiding surfaces hidden) at Valencia.

Figure 4: Shows alaskite midpoint strings (yellow) linked in parallel to the the NE-SW oriented strike of the deposit.

In accordance with National Instrument 43-101 (“NI 43-101”) a Technical Report outlining the mineral resource estimation will be filed under Forsys’ profile on SEDAR+ (www.sedarplus.ca) within 45 days of the date of this release.

Assaying and QAQC

- Recent (2023) Sampling and Assays

- Samples were taken from the diamond drill cores and RC chips for geochemical assay guided by the routine downhole radiometric probe results, and sent to Trace Elements Analysis Laboratories (Pty) Ltd (“TEA Labs”) at Swakopmund for sample preparation and analyses by XRF. For internal quality control purposes TEA Labs has weekly round robins with independent laboratories at Rosh Pinah, Swakop Uranium and Langer Heinrich mines.

- Forsys employs a QAQC programme with Certified Reference Materials (CRMs), blanks, coarse duplicates and pulp duplicates inserted into each batch of samples. The QAQC insert rate comprises 4 % CRMs using three CRM types with different grades of U3O8; 4 % blanks and 8 % to 10 % duplicates. RC sample batches have three types of duplicates; a field duplicate split at the drill rig; a coarse duplicate split at prescribed intervals at the laboratory; and pulp duplicates, also split at the laboratory. Core samples only have coarse and pulp duplicates split at the laboratory.

- Four-percent of the samples sent to TEA Labs are sent for check analyses at SGS Laboratories (SGS) in South Africa, which serves as the independent accredited laboratory. The sample results are further validated by comparison with the radiometric scans.

- Previous Sampling and Assays (2005-2011 Valencia Uranium Limited (VUL)):

- All diamond drill half core and RC samples collected by VUL were assayed at the Setpoint Technology (“Setpoint”) laboratory in Johannesburg, South Africa. Setpoint was accredited with the South African Accreditation System (SANAS), accreditation number T0223, and was also an ISO17025 accredited laboratory. Setpoint crushed and pulverised the samples for analysis of U3O8 using the XRF pressed pellet method.

- The VUL protocols for the QAQC were as follows:

- CRMs inserted at a frequency of at least one per 20 samples.

- Blanks inserted at a frequency of at least one per 50 samples.

- Duplicates taken at a frequency of at least one per 20 samples.

- The Setpoint laboratory included appropriate quality assurance and quality control (QAQC) procedures during the analysis of the VUL samples by including its own certified reference standards (CRM), blanks and duplicates.

- VUL percussion holes were not physically sampled. Datasets were derived from two downhole probes that were calibrated against the XRF sample assays.

- Snowden reviewed the assay results from Setpoint for the Valencia deposits in 20092 for the purposes of resource estimation and considered the QAQC results to be of a high standard of precision, unbiased and accurate.

- Optiro reviewed the assay results from Setpoint for the Namibplaas deposit in 2011 and considered that the results of the QAQC indicate a high level of precision with no bias, no significant contamination and a high degree of accuracy (from Snowden 20092 and Optiro 20113)

- Trekkopje Exploration (Goldfields 1974-1984):

- Exploration data derived from Trekkopje Exploration era, up to and including 1984, have not been verified by the QP and therefore were not utilised in this Mineral Resource Estimate.

Workplan

Forsys is undertaking an infill and extension drilling program and optimisation work with the aim of expanding and upgrading the Mineral Resource:

- Resource Infill Drilling and Resource Extension Drilling

Total of 85 percussion drill holes for 7,520 metres have been laid out on a 25 x 25 metre grid. The objective is to more than double the quantity of the Measured Mineral Resource. The holes target the 660 m elevation with drill depths up to 100 m from surface and is comparable to the previous Measured Resource grid.

A subsequent program for potential resource extension is planned for the areas adjacent to the Valencia Main deposit; along strike to the west, on the hinge zone to the south, and north of the Main deposit at the Jolie Zone. - Pit Design Modeling

The updated resource block model is used to assess open pit economic models. Pit slope design parameters are being reviewed to include lithological logging and geomechanical test work from additional drilling. - Column Leaching Process Optimization Work

Column Leach tests are presently underway at SGS in South Africa where the columns have been emptied and final analyses and data is pending. The next phase of testing will assess systematic processes to enhance the efficiency and effectiveness of extracting the uranium mineralisation from the ore using sulphuric acid solutions. - Process Design

DRA Global were appointed as the study contractor to deliver engineering to support preliminary cost estimates for a heap leach process. Ongoing engineering and optimisation continues. - Bulk Sampling

After site assessment and selection, a detailed plan is being drawn up to develop a box cut with the objective of retrieving approximately 20,000 tonnes of typical run-of-mine, fresh and representative sample material from the deposit.

Qualified Persons Statement for Metallurgy

Mr Aveshan Naidoo is a Specialist Engineer: Hydromet and Economics, for DRA South Africa Projects (Pty) Ltd of Building 33, Woodlands Office Park, 20 Woodlands Drive, Woodlands, Sandton, 2080. He holds a Bachelor of Science in Chemical Engineering and a Master of Business Administration at the University of Witwatersrand. He is a registered Professional Engineer with the Engineering Council of South Africa (Registration No. 20130523). Mr Naidoo has been practising his profession continuously since 2008 and has 16 years of experience across a range of African projects. He is familiar with NI 43-101 and, by reason of his education, experience, and professional registrations, he fulfils the requirements of an independent Qualified Person as defined in NI 43-101.

Qualified Persons Statement for Mineral Resource

The information in this release that relates to the updated Mineral Resource Estimate for the Norasa Project is based on information compiled or reviewed by Dr Guy Freemantle of The MSA Group (Pty) Ltd., Johannesburg, South Africa. The MSA Group are independent consultants to the Norasa Project, Namibia. Dr Freemantle holds a Bachelor of Science in Geology and a PhD in Geology, both at the University of the Witwatersrand. He is a member of the Society of Economic Geologists (892905); a Fellow of the Geological Society of South Africa (965392); and is registered with SACNASP (Registration 117527). Dr Freemantle has practiced his profession continuously for 14 years and has sufficient experience and knowledge that is relevant to the style of mineralisation and type of deposits under consideration as well as to the activity that is being undertaken to fulfil requirements of a Qualified Person as per NI 43-101. Dr Freemantle consents to this release in the form and context in which it appears.

About Forsys Metals Corp.

Forsys Metals Corp. (TSX: FSY, FSE: F2T, NSX: FSY) is an emerging uranium developer focused on advancing its wholly-owned Norasa Uranium Project, located in the politically friendly jurisdiction of Namibia, Africa. The Norasa Uranium Project is comprised of the Valencia Uranium deposit (ML-149) and the nearby Namibplaas Uranium deposit (EPL-3638). Further information is available at the Company website www.forsysmetals.com

On behalf of the Board of Directors of Forsys Metals Corp. Richard Parkhouse, Director, Investor Relations. For additional information please contact:

Pine van Wyk, Country Director, Forsys

email: pine@forsysmetals.com

Richard Parkhouse, Director, Investor Relations

email: rparkhouse@forsysmetals.com email: info@forsysmetals.com

phone : +44 7730493432

Nikolas Matysek, Communications Manager (Canada)

email: nmatysek@forsysmetals.com

Forward Looking Statement

Certain information contained in this press release constitutes "forward-looking information", within the meaning of Canadian legislation. Generally, these forward-looking statements can be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect", "is expected", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur", "be achieved" or "has the potential to". Forward looking statements contained in this press release are qualified in their entirety by the inherent risks and uncertainties surrounding future expectations. Among those factors which could cause actual results to differ materially are the following: market conditions and other risk factors listed from time to time in our reports filed with Canadian securities regulators on SEDAR at www.sedar+.com. The forward-looking statements included in this press release are made as of the date of this press release and Forsys Metals Corp disclaim any intention or obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as expressly required by applicable securities legislation.

1 The Norasa Uranium Project (“Norasa”) is wholly-owned by the Company’s 100% subsidiary Valencia Uranium (Pty) Ltd. (“Valencia Uranium”) and comprises the Valencia uranium deposits (held under ML-149) ("Valencia”) and the Namibplaas uranium deposit (under EPL-3638, application for ML-251) (“Nambiplaas”), located in the Erongo region of Namibia,

2 Valencia Uranium (Pty) Ltd. Valencia Project Namibia Technical Report, Snowden, 2009.

3 Forsys Metals Corp. Technical Report on the Namibplaas Deposit, Namibia, Optiro, 2011

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/2016b8e9-e68f-483e-822b-1424733835e1

https://www.globenewswire.com/NewsRoom/AttachmentNg/f1685ef1-81f0-4936-a3e8-074025530934

https://www.globenewswire.com/NewsRoom/AttachmentNg/09bf2f9e-0ec3-4b95-ac2b-7d8c5269f43b

https://www.globenewswire.com/NewsRoom/AttachmentNg/7103e818-7dd1-42aa-abe6-d85e3ff8d22b

https://www.globenewswire.com/NewsRoom/AttachmentNg/97832d3f-51e4-413f-94c3-52d8e0b1d136